Definition

of Tablets

Tablets

can be defined as Solid Pharmaceutical Dosage form containing drug substances

with or without suitable diluent and

prepare either by compression or moulding methods.

Tablet

Tooling

For this

purpose different types of punches are used:

Flat-

faced bevel- edged.

Shallow

concave (Round/ Capsule shaped)

Standard

concave (Round/ Capsule shaped)

Deep

concave (Round/ Capsule shaped)

Extra

deep.

Modified

ball

The basic mechanical unit in all tablet-compression equipment includes a lower punch which fits into a die from the bottom and an upper punch, having a head of the same shape and dimensions, which enters the die cavity from the top after tablet material fills the die cavity.

The basic mechanical unit in all tablet-compression equipment includes a lower punch which fits into a die from the bottom and an upper punch, having a head of the same shape and dimensions, which enters the die cavity from the top after tablet material fills the die cavity.

PROCUREMENT

OF TOOLING

While

ordering any punch set (From Approved Supplier only), following

things should be covered:

- Drawing for upper/lower punch / die, by the manufacturer as per the specifications given or as per sample punch set.

- Following details should be given with the purchase order:

•

Total number of set required

•

Type of punch set eg. D/B/BB etc.

•

MOC to be used (HCHC/OHNS)

HCHC: High Carbon High Chromium

OHNS: Oil Hardened non shrinking Steel

• Engraving

details; Sr. no., Mfr name, Date of Mfg., Punch size in mm.

•

Special requirements like: Concavity, embossing, chrome plating

etc.

Tablet

Tooling

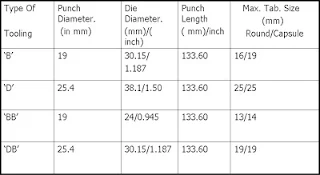

‘B’ -Tooling

‘D’ - Tooling

‘BB’

-Tooling

'DB’ - Tooling

'DB’ - Tooling

Tablet

Tooling Parts

Following definitions for

direct terminology for tooling (Punches and dies).

1. Head: The end of the punch that guides it through the

cam track of tablet machine during rotation.

2. Head flat (Dwell Flat): The flat area of the head

that receives the compression force from rollers (in upper punches) and

determines the weight and ejection height (in lower punches).

3. Outside head Angle: The area gets in touch

with the roller prior to head flat, while compression.

4. Inside Head Angle:This is the area, which

pulls down the lower punches after ejection and lifts the upper punches after

compression.

5. Neck: The relived area between the head and barrel,

which provides clearance for the cams.

6. Barrel: This area guides the punch (while going up and

down) with reference to turret guides.

7. Stem: The area of the punch opposite the head,

beginning at the tip and extending to the point where the full diameter of the

barrel begins. If the chamfer is present the barrel usually reaches its full

diameter just above the chamfer.

8. Tip: This determines size, shape & profile of

the tablet.

9. Tip face: This area of punch is

where the tablet is formed. Good surface finish is required here to bet quality

tablets.

Working length: This distance between bottom of the cup and

the head flat is called as working length which determines weight and thickness

of the tablet.

10. Overall length: Distance between top of

the cup and the head flat.

11. Key Angle: The relationship of the

punch key to the tablet shape. The keys position is influenced by the tablet

shape, take-off angle, and turret rotation.

12. Domed Heads: Increases the dwell time and hence help

to achieve the better tablet hardness.

13. Dwell time: The time punches spends

below the pressure roller while rotating in the machine.